Sustainable electronics for the future: insights from ARMS coordinator Prof. Matti Mäntysalo

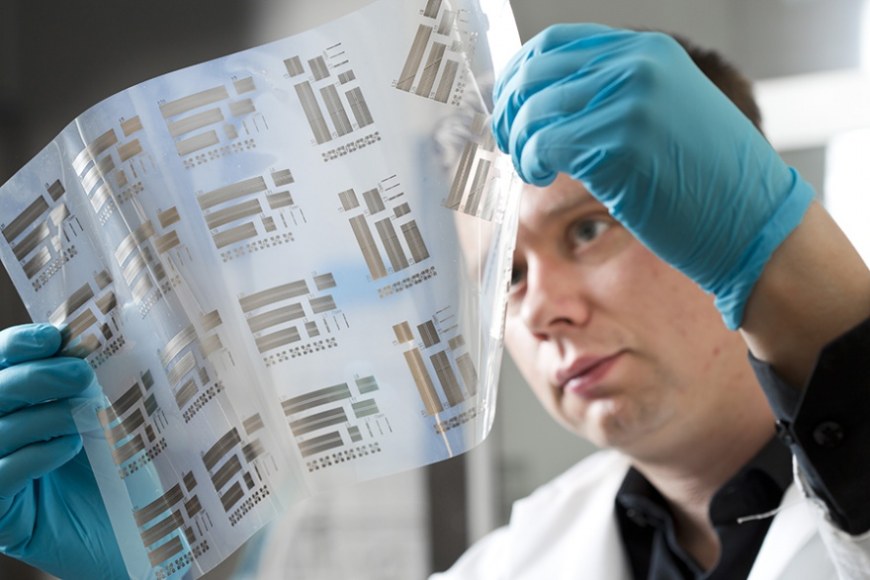

P Prof. Matti Mäntysalo studying printed electronics. Photo - Tampere University.

Prof. Matti Mäntysalo studying printed electronics. Photo - Tampere University.

Recently, Tampere University website published an interview with project ARMS coordinator Prof. Matti Mäntysalo. In the interview, he shares how his team at Tampere University is reshaping electronics manufacturing toward sustainability, efficiency, and circular‑economy principles. Prof. Mäntysalo's research focuses on printed and additive manufacturing, in which electronics are built using minimal material, low temperatures, and far fewer chemicals, enabling bio‑based, biodegradable, and low‑energy components.

These breakthroughs directly support the ARMS mission to develop eco‑friendly, high‑performance supercapacitors using scalable processes and sustainable carbon‑based materials. Mäntysalo’s team also explores alternatives to critical raw materials and promotes new paths for environmental and healthcare applications, from biodegradable soil sensors to low‑cost wearable diagnostics.

His vision reflects the core of ARMS: smarter materials, cleaner manufacturing, and real‑world impact made possible through strong industry collaboration.

CIDETEC Energy Storage: bridging advanced materials and industrial energy storage devices

CIDETEC Energy Storage is an applied research centre specialising in advanced energy storage technologies. We develop battery technologies from the materials level through to the manufacturing and validation of cells at pre-industrial scale, covering the entire value chain. Our mission is to accelerate technology transfer to industry and support a sustainable energy transition in Europe.

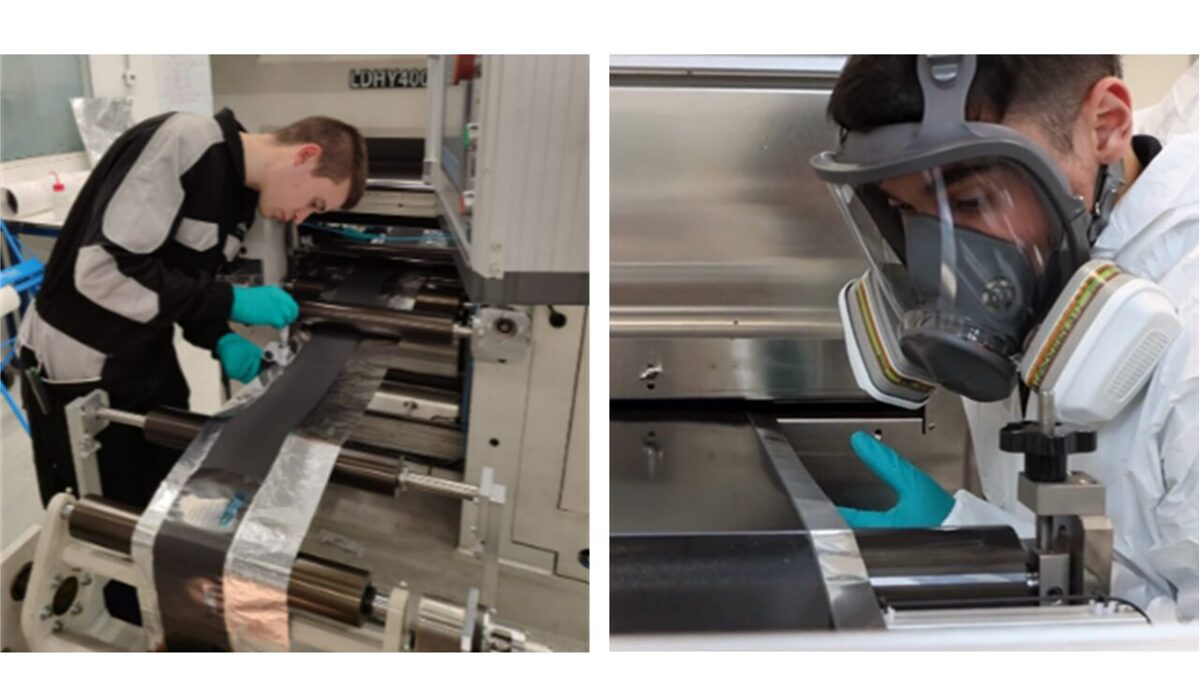

Within the ARMS project, CIDETEC Energy Storage contributes its expertise as the partner responsible for translating technologies developed in the initial work packages into functional devices. Our team specialises in electrode processing and pilot-scale cell assembly, bringing extensive experience in adapting emerging technologies to industrial manufacturing processes.

As part of ARMS, CIDETEC plays a key role in WP2 (Electrode Fabrication). In this work package, based on the active materials developed earlier in the project, our team optimises electrode formulations and processing steps, including mixing, roll-to-roll coating, drying, and calendering. The objective is to produce stable, high-quality electrodes that are fully compatible with cell assembly.

In parallel, within WP5 (Supercapacitor Device Integration and Demonstration), CIDETEC is responsible for assembling asymmetric cells using multi-layer stacking processes and Z-folded separators. This includes critical steps such as electrolyte filling, conditioning, and cell sealing. Following successful validation of the electrochemical performance of the new materials—aimed at increasing energy density without compromising power capability or cycle life—these cells will be deployed as replacements in wireless environmental monitoring applications.

From Laboratory Innovation to Industrial Manufacturing

Scaling ALD for Supercapacitor Production in the ARMS Program

Moving supercapacitor innovations from laboratory research to industrial manufacturing requires early focus on scalability. Within the ARMS program, Beneq’s role is to translate academic atomic layer deposition (ALD) processes into stable, manufacturable solutions suitable for production environments.

From Proof to Manufacturable Reality

Within ARMS, materials and ALD processes are first validated on Beneq TFS 200 R&D equipment in academic laboratories.

Progress toward manufacturing requires a shift from experimental optimization to defined operating conditions suitable for reliable, repeatable production.

This shift is governed by practical requirements such as substrate format, output volume, throughput, thermal limits, and cost, guiding process transfer from laboratory tools to industrial batch ALD, and onward to large batch scale equipment and spatial roll-to-roll platforms.

What Beneq Delivers in ARMS

Beneq is responsible for de-risking the transition from validated ALD concepts to industrially deployable processes. This includes selecting scalable approaches, adapting them to production-grade ALD platforms, and verifying performance under manufacturing-relevant conditions.

Proven Industrial ALD Platforms

Beneq’s contribution to ARMS builds on extensive experience in industrial ALD across multiple markets:

- P-series batch ALD for high-volume semiconductor component coating

- SCS 1000 sheet-to-sheet coater, for high-throughput prototyping

- Genesis roll-to-roll ALD for continuous, high-throughput manufacturing

Beneq P1500, world’s largest batch ALD

production platform

Beneq P1500, world’s largest batch ALD

production platform

These platforms represent established and emerging production use cases, demonstrating Beneq’s ability to scale ALD to industrial manufacturing.

Expertise Driving Commercialization

ARMS activities at Beneq are led by Dr. Andrew Cook, whose background in spatial ALD and industrial scale-up supports the transition of laboratory innovations into production-ready processes since 2014. Together with Beneq’s spatial ALD team, he brings extensive experience in commercializing ALD technologies across thin-film processing, optical, and energy-related applications.

Dr. Andrew Cook with the Beneq WCS 600

roll-to-roll system (image credit: CPI UK)

Dr. Andrew Cook with the Beneq WCS 600

roll-to-roll system (image credit: CPI UK)

Enabling Industrial Impact

Through ARMS, Beneq supports the progression of supercapacitor technologies from laboratory innovation to industrial reality. By combining ALD expertise, scalable platforms, and manufacturing-focused development, Beneq helps ensure that promising research outcomes can be realized at production scale.

Chalmers University develops versatile method for enhanced supercapacitor performance in ARMS project

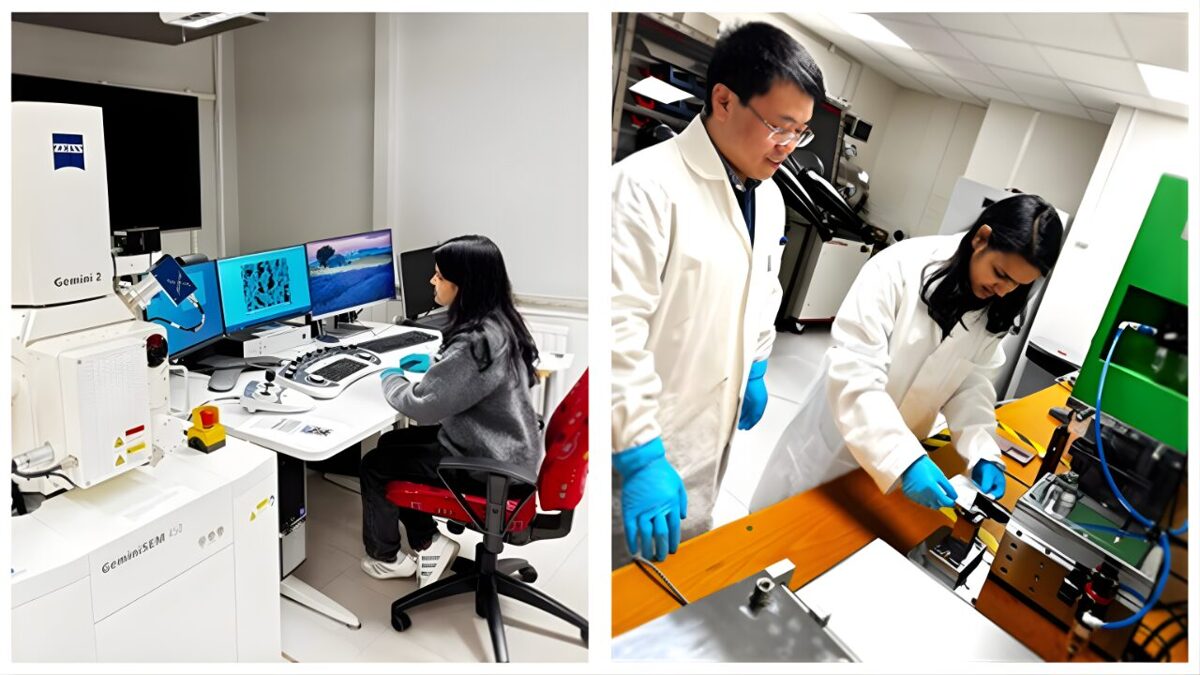

Chalmers University of Technology (Associate Professor Jinhua Sun and PhD student Komal Gola), as one of the partners in the ARMS Project, has developed a versatile method in collaboration with other partners to grow vertical and porous graphene on the surface of structural carbon fiber materials, significantly enhancing supercapacitor performance.

The Jinhua Sun Research Group at Chalmers has more than 10 years of research experience in graphene and related materials. The team has strong expertise in surface chemistry modification, synthesis of graphene-based composites, and integration with functional materials such as polymers, metals, semiconductors, and metal oxides. These advanced composites are applied across a wide range of fields, including supercapacitors, lithium-ion, sodium-ion, and aluminum-ion batteries, as well as sensors, gas barriers, tribology, anticorrosion coatings, and thermal management.

Within ARMS, the Chalmers team focuses on developing a versatile processing method to grow vertical graphene on carbon fiber surfaces. This approach aims to increase surface area, porosity, electrochemical performance, and mechanical properties of carbon fiber-based electrodes. Various graphene derivatives—such as graphene oxide, reduced graphene oxide, and mechanically exfoliated graphene—are used as starting materials to form vertical structures on carbon fibers. The graphene density on the fiber surface can be precisely controlled, enabling tuning of surface area and porosity for optimized supercapacitor performance.

Importantly, in collaboration with the ALD team within ARMS, metal oxide-based active materials have been successfully deposited on the vertical graphene surface, dramatically improving the performance of structural supercapacitors.

At Chalmers, advanced characterization techniques are employed to analyze the structure, morphology, surface chemistry, thermal stability, and mechanical properties of graphene-reinforced carbon fiber electrodes. These electrodes, featuring vertically grown graphene, have been used to fabricate high-performance supercapacitors in various configurations, including three-electrode cells, coin cells, and multilayer pouch cells. While optimization is ongoing, the results show promising improvements.

Project ARMS showcased at Tampere University’s ITC Faculty Research Afternoon

On October 30th, Project ARMS was proudly showcased at the Research Afternoon hosted by the Faculty of Information Technology and Communication Sciences (ITC) at Tampere University’s Hervanta campus. The event brought together a vibrant community of researchers, students, and innovators to share insights and foster interdisciplinary collaboration.

Dr. Hamed Pourkheirollah represented ARMS at the Electronics Research Center (ERC) booth, where he presented the project’s latest developments through an engaging visual display. Visitors had the opportunity to explore the project’s goals, ask questions, and take home printed leaflets for further reading. The booth attracted interest from across the faculty, sparking conversations about the project’s potential impact and future directions.

Beyond showcasing ARMS, the event served as a platform to discover the diverse research activities underway at Tampere University. It encouraged knowledge exchange and opened doors to potential new collaborations.

Adding a light-hearted twist to the afternoon, a friendly competition was held—and Dr. Pourkheirollah was among the winners, adding a celebratory note to the day. The event concluded with a networking dinner at the Reaktori restaurant, marking the end of an inspiring afternoon of science, innovation, and community spirit.

Key Takeaways:

- ARMS gained visibility among a broader academic audience.

- The event facilitated new connections and potential future collaborations.

- The interactive format helped communicate the project’s goals in an engaging way.

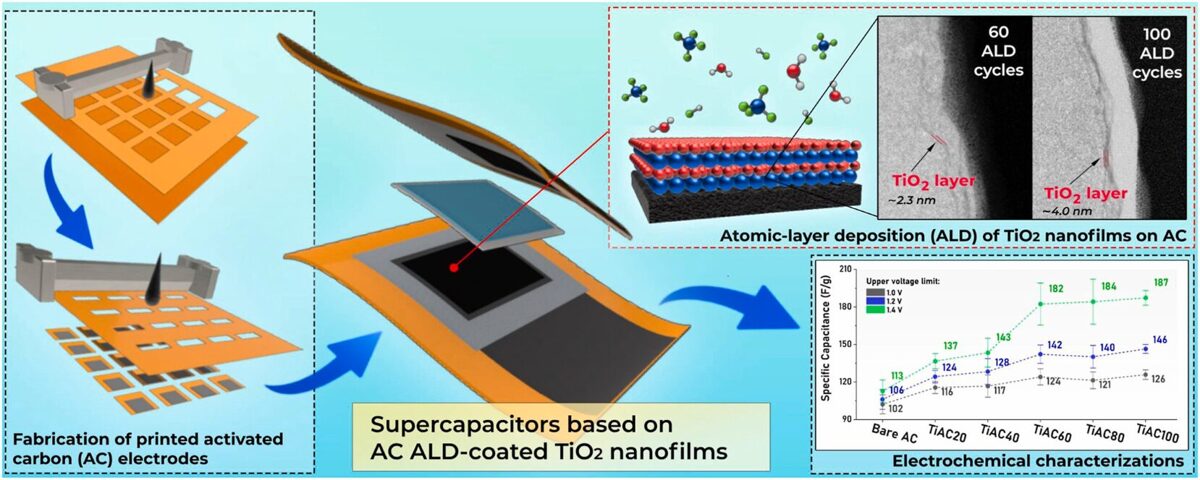

ARMS publication featured in Journal of Power Sources

Graphical abstract of the publication

Graphical abstract of the publication

The ARMS project is proud to announce the publication of a scientific article in the Journal of Power Sources (662 (2026); 238691). The article, titled "Interfacial engineering of conformal titanium oxide nanofilms on porous carbon supercapacitor electrodes via atomic layer deposition", presents an advancement in the development of high-performance, sustainable energy storage devices.

The research was conducted by a multidisciplinary team:

- Remuel Isaac M. Vitto, Hamed Pourkheirollah, Jari Keskinen, Amit Tewari, Donald Lupo, Paul R. Berger, and Matti Mäntysalo from Tampere University, Finland

- Steffen Vindt from InnoCell ApS, Denmark

- Andrew Cook from Beneq Oy, Finland

- Līga Grīnberga, Līga Ignatāne, and Gints Kučinskis from the Institute of Solid State Physics, University of Latvia

- Aleksandrs Volperts from the Latvian State Institute of Wood Chemistry

The study presents a novel approach to enhancing the electrochemical performance of supercapacitors by coating porous activated carbon (AC) electrodes with ultra-thin titanium dioxide (TiO₂) nanofilms using atomic layer deposition (ALD). The authors developed a low-temperature ALD process (120 °C) using TiCl₄ and H₂O precursors, optimized for high surface area substrates like AC.

The motivation stems from the need to improve the energy density of supercapacitors, which traditionally lag behind lithium-ion batteries. By integrating pseudocapacitive materials such as TiO₂ with AC, the researchers aimed to combine electric double-layer capacitance (EDLC) with faradaic redox reactions for enhanced performance.

Key findings include:

- The TiO₂ nanofilms were amorphous, highly uniform, and conformal, as confirmed by SEM, TEM, and XPS analyses.

- Optimal performance was achieved at 60 ALD cycles (~2.3 nm film thickness), resulting in a 61% increase in specific capacitance compared to bare AC.

- The dominant energy storage mechanism was surface redox reactions, with some contribution from intercalation-type pseudocapacitance.

- Excessive film thickness led to pore blocking and reduced performance, highlighting the importance of precise thickness control.

The study concludes that this ALD-based interfacial engineering strategy offers a scalable and sustainable route to next-generation high-performance supercapacitors, particularly suitable for flexible and printed electronics.

Building the future of energy storage: ARMS 5th Consortium Meeting

ARMS consortium partners at the SDU

ARMS consortium partners at the SDU

The ARMS consortium gathered for its 5th Consortium Meeting on October 23–24, 2025, hosted across two inspiring locations in Denmark: the Faculty of Engineering (TEK) at the University of Southern Denmark in Odense, and the innovation hub Innocell ApS in Svendborg.

The two-day event brought together project partners from across Europe to share progress, exchange ideas, and deepen collaboration on the ARMS initiative. The meeting opened with warm words of welcome from the hosts and project coordinator, setting the tone for a productive and collegial atmosphere. Smiles, handshakes, and fresh coffee helped kick off what would become a dynamic and fruitful gathering.

Day 1: Technical Deep Dive and Faculty of Engineering Tour

The first day in Odense was filled with presentations from each work package, highlighting the impressive progress made across the consortium as the project approached the beginning of its third year:

- WP1 (Institute of Solid State Physics, University of Latvia) kicked off the technical sessions with a strong overview of recent developments, followed by insightful updates from WP2 (KTH Royal Institute of Technology) and WP3 (Tampere University)

- After a well-earned lunch break, the afternoon continued with engaging contributions from WP4 (Innocell ApS), WP5 (Cidetec Energy Storage), WP6 (University of Southern Denmark), and WP7 (BENEQ). Each presentation sparked lively discussions and valuable feedback from fellow partners.

Day 1 of the ARMS consortium meeting

Day 1 of the ARMS consortium meeting

- The day concluded with a guided tour of the TEK facilities at the University of Southern Denmark, offering participants a closer look at its cutting-edge infrastructure.

ARMS partners visit SDU's Faculty of Engineering

ARMS partners visit SDU's Faculty of Engineering

Day 2: Strategic Outlook and Innovation

The second day took place in Svendborg and began with a presentation from WP8 (Tampere University), focusing on project management matters. The session provided clarity on administrative aspects and helped align the consortium on upcoming milestones.

Day 2 of the ARMS consortium meeting at InnoCell

Day 2 of the ARMS consortium meeting at InnoCell

This was followed by a forward-looking discussion on collaboration with the Graphene Flagship, reinforcing ARMS’ commitment to broader European research initiatives and opening doors to new synergies.

At the conclusion of the meeting, external advisor Dr. Jakob Heier from EMPA – Swiss Federal Laboratories for Materials Science and Technology provided valuable feedback on the project’s progress.

ARMS consortium partners at InnoCell ApS

ARMS consortium partners at InnoCell ApS

The meeting wrapped up with a tour of Innocell ApS, where participants explored the innovation space and discussed future opportunities. A final lunch in Svendborg offered a relaxed moment to reflect on the two days of intense collaboration and shared vision.

ARMS consortium partners at the InnoCell labs in Svendborg

ARMS consortium partners at the InnoCell labs in Svendborg

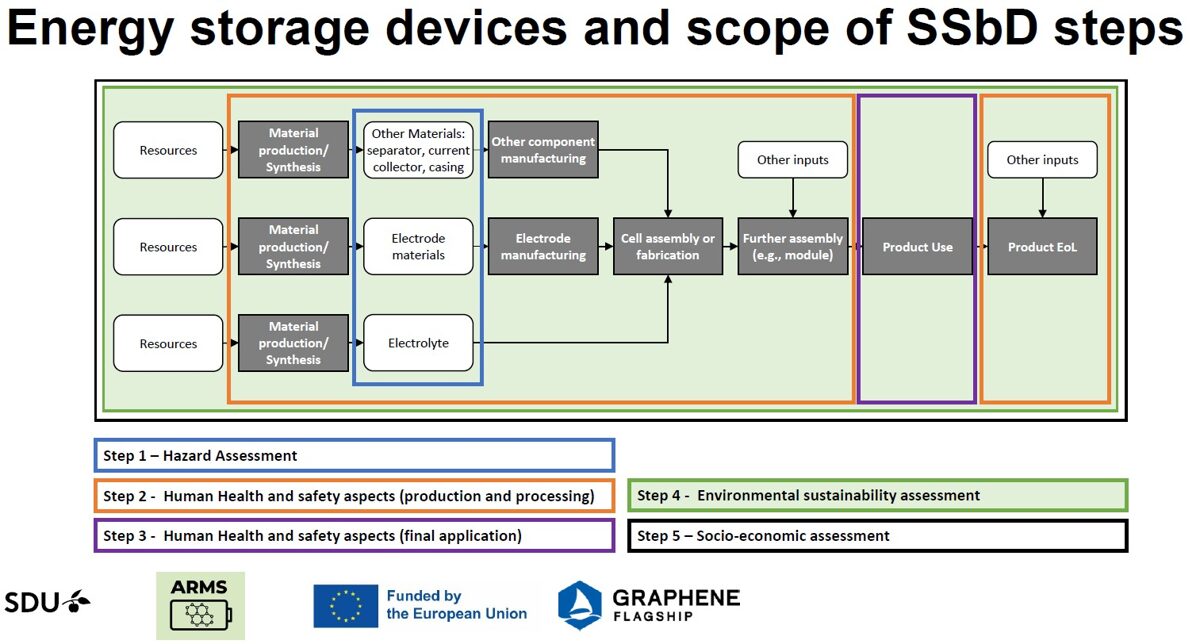

Designing Safety: SDU’s Role in Building the SSbD Framework

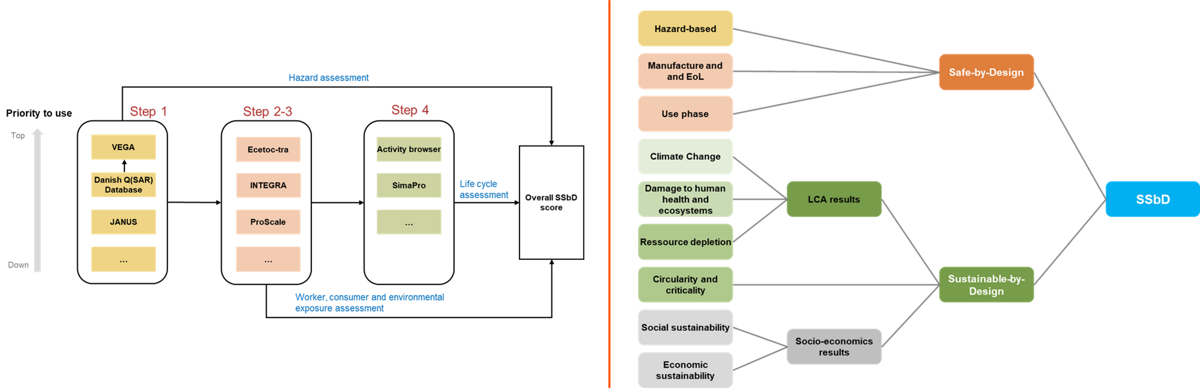

Mapping SSbD Across the Lifecycle of Energy Storage Devices

Within the ARMS project, the team from the University of Southern Denmark (SDU) is currently focused on developing and testing a robust, transparent, and user-friendly approach to safety assessment, which represents the first part of the Safe and Sustainable by Design (SSbD) framework. Our aim is to explore how various tools and data sources can be integrated to deliver consistent, reliable, and meaningful results that support safe material innovation.

A key challenge lies in evaluating the strengths and limitations of different hazard assessment tools, such as the VEGA Hub. Each tool operates based on distinct models and assumptions, so part of our work involves comparing their outputs and assessing their reliability. To ensure consistency, we also incorporate information from safety data sheets, which serve as a baseline for cross-checking model-generated results. This approach helps us identify where tools converge, where they differ, and how these differences can be communicated transparently within the SSbD framework.

For exposure assessment, we are developing an independent data collection framework in collaboration with other ARMS work packages. This is a demanding yet rewarding process, involving multiple rounds of data correction, updating, and refinement. Our goal is to make exposure assessment feasible and consistent—even when detailed data are limited—marking an important step toward a unified and practical SSbD approach.

Through this iterative process, we’ve learned that achieving SSbD is not just about building models or compiling datasets. It’s equally about fostering coherence and trust across diverse sources of knowledge.

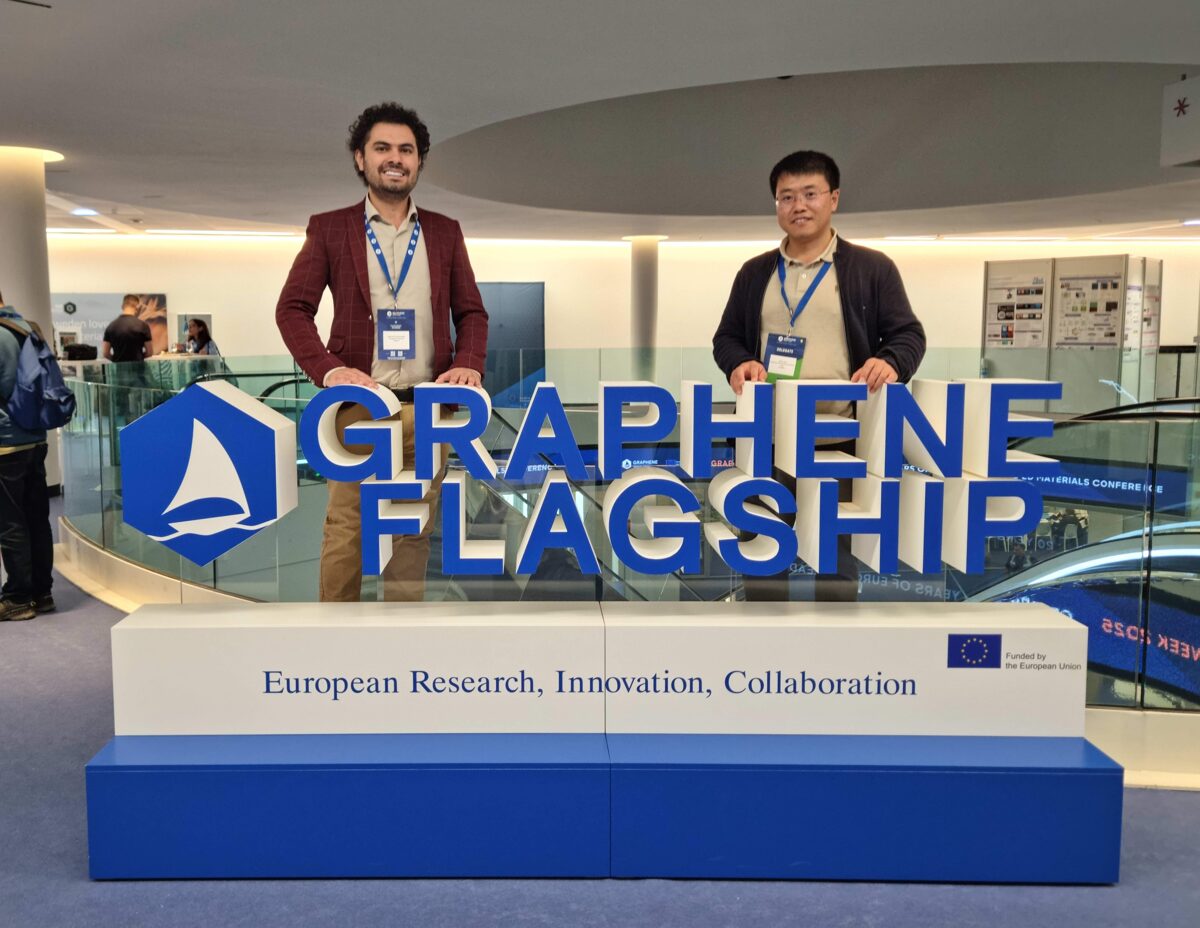

Project ARMS at Graphene Week 2025: Showcasing Innovation in 2D Materials

From September 22 to 26, the city of Vicenza, Italy, hosted Graphene Week 2025, Europe’s leading event dedicated to graphene and related 2D materials. This year, Project ARMS was proud to be part of the vibrant scientific community gathered to explore the future of advanced materials.

Representing the ARMS consortium were Hamed Pourkheirollah from Tampere University and Jinhua Sun from Chalmers University of Technology, both of whom played an active role in showcasing the project’s progress and engaging with fellow researchers.

Graphene Week provided an excellent platform to connect with experts from

across Europe and beyond. Hamed and Jinhua engaged in meaningful discussions on

the diverse applications of graphene and 2D materials, from electronics to

energy systems.

Project ARMS hosted a dedicated booth at the event, where visitors could

learn about the project’s objectives, recent developments, and future

directions. The booth served as a hub for exchanging ideas and exploring

potential collaborations with other EU-funded initiatives and research groups.

A key highlight was the presentation of Project ARMS during the annual

meeting, where Hamed and Jinhua introduced the project to the broader

graphene community. Their talk emphasized ARMS’s mission to advance the

integration of 2D materials into real-world applications, particularly in the

field of energy storage and conversion.

The ARMS team also participated in the Project Managers Network meeting, a valuable

opportunity to share experiences and strengthen synergies across EU-funded

projects. This collaborative spirit is central to the success of initiatives

like ARMS, which thrive on interdisciplinary exchange.

In addition to the official program, Hamed and Jinhua joined a podcast

recording organized by the GRAPHERGIA project, hosted by Maria

Abrahamsson, Director of the Graphene Flagship. The discussion focused on

the role of graphene and 2D materials in energy storage systems,

offering insights into how ARMS is contributing to this transformative field.

Project ARMS extends its gratitude to the Graphene Flagship for

organizing such a well-curated and impactful event. Graphene Week 2025 was not

only a showcase of scientific excellence but also a celebration of

collaboration and innovation.

More information about the Graphene Week 2025.

Project ARMS represented at the IEEE FLEPS 2025 in Singapore

From June 22 to 25, 2025, the Project ARMS representative Chirag Mevada from Tampere University had the opportunity to

participate in the IEEE International Conference on Flexible and Printable

Sensors and Systems (FLEPS 2025), held at the National University of

Singapore (NUS). This prestigious annual event brought together leading

minds from academia, industry, and government to explore the latest

advancements in flexible electronics and sensor technologies.

Chirag Mevada was proud to showcase our latest research during the conference. Our participation included a poster presentation, “Long-Term Performance of Activated Wood Carbon Printed Supercapacitors: A Sustainable Alternative to Conventional Activated Carbon”. In this work, the project demonstrated the long-term cycling performance of printed supercapacitors made from Latvian State Institute of Wood Chemistry’s alder wood carbon material, outperforming the commercial Kurraray YP-80F supercapacitors over 10,000 charge-discharge cycles.

IEEE FLEPS 2025 served as a dynamic platform for researchers, engineers, and innovators to present cutting-edge developments in the field of flexible and printable electronics. The conference attracted a diverse international audience, with participants representing institutions and companies from across Asia, Europe, North America, and Australia. The global nature of the event fostered rich discussions and cross-disciplinary collaboration.

The conference program featured a robust lineup of plenary talks, invited presentations, technical sessions, and industry panels. Topics covered included:

- Printed and stretchable sensors

- Flexible hybrid electronics

- Bio-integrated and wearable systems

- Energy harvesting and storage

- Emerging materials and fabrication techniques

- Standardization efforts in flexible electronics

Notable speakers included experts from the leading scientific institutions and industry. Their insights highlighted both the scientific progress and the real-world applications of flexible sensor technologies in areas such as healthcare, robotics, and the Internet of Things (IoT).

For project ARMS, the IEEE FLEPS 2025 provided valuable exposure to emerging trends and technologies that align closely with our project’s goals. The event also reaffirmed the importance of interdisciplinary collaboration and the growing impact of flexible electronics on modern technology. We are excited to integrate the insights gained from the conference into our ongoing work and to continue contributing to this rapidly evolving field.

Our work, presented at the conference,

has been published in its proceedings (DOI: 10.1109/FLEPS65444.2025.11105690).

For more information about the conference, please visit the IEEE FLEPS 2025 website.

Fostering global dialogue on sustainability: ARMS at ISIE2025

Representatives of SDU’s Center for Life Cycle Engineering at the 12th ISIE Conference

Representatives of SDU’s Center for Life Cycle Engineering at the 12th ISIE Conference

Project ARMS consortium partners from the University of Southern Denmark (SDU), Ciprian Cipman and Suiting Ding, represented our project at the 12th International Conference on Industrial Ecology (ISIE2025), held from July 1-4, 2025, at the National University of Singapore.

ARMS was actively present at ISIE2025, where Ciprian Cipman delivered a presentation on our latest work applying Safe and Sustainable by Design (SSbD) principles to the development of next-generation electrochemical energy storage devices. The SSbD framework can help researchers and industry integrate safety, life cycle thinking, and circularity into next-gen battery and supercapacitor development, ensuring responsible solutions from lab to market.

Our representatives were proud to contribute to the global dialogue on industrial ecology. The conference featured a wealth of inspiring presentations, engaging discussions, and valuable networking opportunities—both with long-standing collaborators and new connections.

Ciprian Cipman (SDU) presenting the latest research at the ISIE2025.

Ciprian Cipman (SDU) presenting the latest research at the ISIE2025.

The theme of the conference, Interconnectivity—recognizing mutual dependencies—highlighted the relationships between industry, society, governance, and the environment; the various scales of human settlements; and the circular material and political relations that are central to the worldview of industrial ecology. The event brought together professionals, academics, and students from around the world to share ideas, insights, innovations, and methods related to industrial ecology.

As the flagship conference on Industrial Ecology, ISIE2025 emphasized our interconnectedness and addressed the challenges facing the world today. The conference explored necessary changes to stay within planetary boundaries and discussed technical, behavioral, and organizational solutions to meet these challenges.

For more information about the conference, please visit the ISIE2025 website

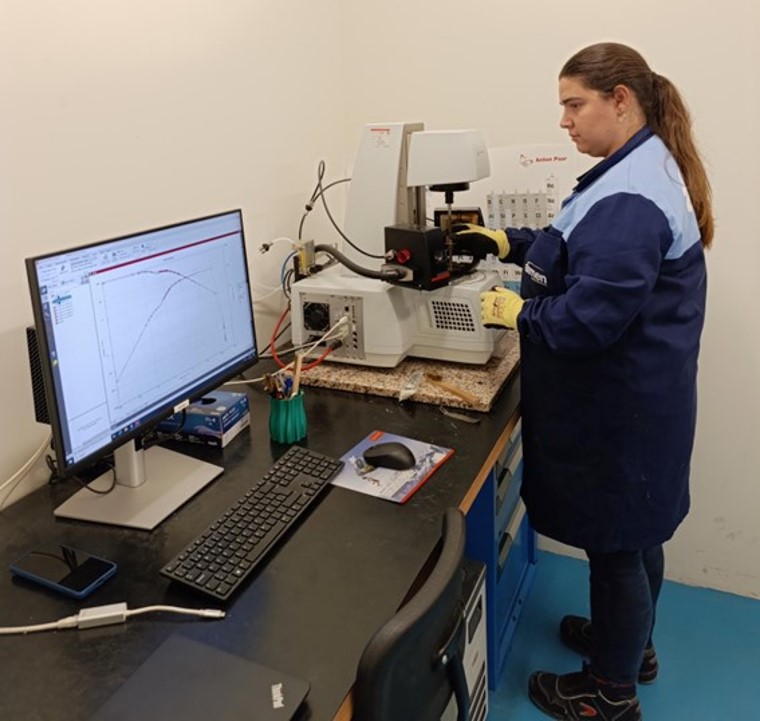

AIMEN advances electrode characterization and electrolyte optimization within the ARMS project

Project ARMS team at the AIMEN Technology Centre

Project ARMS team at the AIMEN Technology Centre

Within the framework of the European project ARMS (Atomic layer-coated gRaphene electrode-based Micro-flexible and Structural supercapacitors), the AIMEN Technology Centre is contributing to the development of structural energy storage materials. AIMEN has recently completed experimental activities within Work Package 2 (Electrode Fabrication) and Work Package 4 (Electrolyte), focused respectively on electrode characterization and electrolyte formulation for structural supercapacitor devices.

As part of WP2, AIMEN has been responsible for activating carbon fibres through pre-treatment processes and supplying the activated materials to project partners for subsequent functionalization. The KTH Royal Institute of Technology applies activated carbon (AC) and electrochemical exfoliated graphene (EEC) coatings by dipping, while the Chalmers University of Technology (CUT) performs graphene and MXene deposition. AIMEN has conducted electrochemical characterization of the coated electrodes to assess their performance under different configurations and operational conditions.

Image 1 and Image 2

Image 1 and Image 2

This work involves the use of Cyclic Voltammetry (CV) and Galvanostatic Charge-Discharge (GCPL) techniques to evaluate the capacitance behaviour of the electrodes in different setups and various electrolyte environments (Image 1 and Image 2), including aqueous (NaCl-H2O), hybrid (NaClO₄-PC/H₂O), and ionic liquid-based systems (EMIMTSFI). The results indicate capacitance increases between 10 and 20 times compared to untreated carbon fibres, highlighting the effect of fibre activation and coating processes. Testing has also identified operational voltage ranges between 1.5 and 2 volts, within which the electrodes maintain stable cycling behaviour.

In WP4, AIMEN is leading the development of electrolyte-resin systems intended for integration into structural supercapacitor manufacturing. This work involves screening epoxy resins and ionic liquid electrolytes to identify formulations that exhibit suitable processability and electrochemical performance.

Image 3

Image 3

AIMEN applies rheological analysis (Image 3) to monitor viscosity changes during thermal curing, assessing the suitability of the material for manufacturing processes such as vacuum-assisted resin infusion (VARI). The ionic conductivity of these systems is evaluated using Electrochemical Impedance Spectroscopy (EIS) before and after curing. Initial results show an increase in ionic conductivity of approximately two orders of magnitude in formulations containing ionic liquids compared to neat resins, while maintaining viscosity ranges suitable for infusion processes.

Next steps in WP2 will include the characterization of activated carbon and graphene-MXene-coated fibres on larger sample formats. In WP4, work will continue on optimizing resin and ionic liquid mixtures. These developments will contribute to WP5 (Supercapacitor Device Integration and Demonstration), where supercapacitor devices will be manufactured using the VARI process. The first manufacturing trials of structural supercapacitors using this approach are planned in the next phase of the project.Bridging science and innovation: ARMS team at the Carbon 2025 conference

From June 29 to July 4, 2025, the historic coastal city of Saint-Malo, Brittany, France, became a vibrant hub for groundbreaking research and collaboration during the Carbon 2025 Conference — an esteemed international gathering dedicated to advancing carbon science and its diverse applications. Carbon materials experts from around the world convened to share insights, foster collaborations, and explore emerging trends.

Project ARMS was represented at this gathering by researchers from the Latvian State Institute of Wood Chemistry (LSIWC), Ance Pļavniece and Aleksandrs Volperts. The conference provided a valuable platform to showcase our innovative work and engage with global leaders in the field.

Dr.sc.ing. Aleksandrs Volperts’ presentation on advanced activated carbon materials and their applications in electrochemical energy storage, specifically in supercapacitors (electrochemical double-layer capacitors, EDLCs). Supported by the Project ARMS, his research contributed to the growing knowledge base on sustainable energy storage solutions and the role of carbon materials in next-generation devices.

The conference featured five outstanding plenary lectures delivered by internationally recognized experts, highlighting advances in both fundamental research and practical applications of carbon materials:

- Prof. Fernando Pereira – “Tailoring carbon surface chemistry: Catalytic applications for sustainable solutions” – exploring carbon surface functionalization for heterogeneous catalysis;

- Prof. Patrice Simon – “2- and 3-D carbons for electrochemical energy storage applications” – discussing porous and layered carbon structures, including graphene-based materials;

- Prof. Yan Li – “Carbon nanotubes as semiconducting materials: synthesis, sorting, and assembly” – focusing on carbon nanotube applications in nanoelectronics;

- Prof. Vincent Meunier – “Decoding Raman Signatures in Carbon Nanostructures: A First-Principles Perspective on Phonons” – providing insight into interpreting Raman spectroscopy in nanostructured carbon materials;

- Prof. Fedor Jelezko – “Spin qubits in diamond” – presenting cutting-edge research on quantum information processing using spin qubits embedded in diamond lattices.

Participation in Carbon 2025 provided an excellent platform for our project partners to disseminate the latest project results, exchange ideas with peers, explore collaboration opportunities, and stay updated on emerging trends in carbon materials research.

ARMS consortium partner InnoCell shares insights into their key team members

As a dedicated partner in the ARMS project, InnoCell is proud to showcase the talented individuals driving innovation and development within their organization. Despite being a small but agile company, InnoCell’s team is composed of versatile experts who wear multiple hats to bring cutting-edge energy storage solutions to market. Today, we introduce two essential members of the InnoCell team: Lead Quality Engineer Jeanne-Louise S. Lundsgaard and Production Manager Jens Riber, providing a glimpse into their vital roles and contributions.

Jeanne-Louise S. Lundsgaard has been an integral part of InnoCell since its inception in 2016. With a background as a chemical engineer and a Master’s degree in Environmental Engineering, Jeanne-Louise’s expertise spans development, patent management, and project leadership. She oversees the development of innovative materials such as the corrosion-preventive layer for hybrid electrolyte supercapacitors and organic electrolyte pouch cell supercapacitors, including electrode and coating development.

Her responsibilities extend to performance testing—conducting standardized electrochemical tests and accelerated stress assessments—to ensure the reliability and efficiency of InnoCell’s products. Jeanne-Louise also manages patent applications and intellectual property, safeguarding the company’s innovations. Her extensive background includes consulting on sustainable solutions, electrode development for direct methanol fuel cells, and pioneering early fuel cell prototypes, including a 1 kW DMFC system.

Jens Riber, aged 58, joined InnoCell in late 2022. With a solid educational background as a Production Engineer, complemented by NLP coaching certification and professional Toolmaker training, Jens brings decades of experience from the automation and electronics manufacturing industries. His primary focus is on developing and refining production processes—creating Standard Operating Procedures (SOPs), ensuring equipment performs within specifications, and maintaining a seamless supply chain to support ongoing development and prototyping.

Jens’s expertise in automation and manufacturing enables him to continuously improve production techniques, ensuring that InnoCell’s prototypes meet the highest quality and performance standards. His work ensures that the company’s innovative energy storage solutions are manufactured efficiently and reliably, pushing the boundaries of what’s possible in energy technology.

Looking Ahead

The combined efforts of Jeanne-Louise and Jens exemplify InnoCell’s commitment to innovation, quality, and manufacturing excellence. Their diverse skills and dedication are vital to advancing the ARMS project and bringing sustainable energy solutions closer to market.

ARMS showcases innovative energy storage solutions at EU-Korea Workshop

On May 26, Hamed Pourkheirollah, ARMS representative from Tampere University, participated in the 9th EU-Korea Workshop on Graphene and 2D Materials, organized by 2D PRINTABLE in Strasbourg, France. His presentation focused on innovative supercapacitor materials, highlighting the progress of the ARMS project in energy storage technology.

This event reinforced the longstanding collaboration between the Graphene Flagship and the Korean Graphene Society. Its primary goal was to facilitate the exchange of ideas and best practices on topics such as the synthesis and production of 2D materials, their physical and chemical properties, and their applications in (opto)electronics, energy, and composites.

The workshop featured distinguished speakers from the Graphene Flagship, European research institutions, and leading Korean universities, including KAIST, SKKU, Yonsei University, Pusan National University, and Kyung Hee University. Maria Abrahamsson, Director of the Graphene Flagship, represented the organization. Experts from initiatives like 2D PRINTABLE, 2D-PL, 2D NEURALVISION, GRAPHERGIA, ARMS, and GIANCE shared their latest advancements, emphasizing the strength of international collaboration in 2D materials.

In his presentation, titled ‘Advancements in Supercapacitor Technology: Optimizing Graphene-Enhanced Carbon Materials for Printed Supercapacitor Applications’, Hamed Pourkheirollah detailed how different processing methods and temperatures produce Activated Wood Carbon (AWC) with unique pore structures, significantly boosting supercapacitor performance. The ARMS team achieved a specific capacitance of 249 F/g and an energy density of 49.8 Wh/kg, surpassing many commercial supercapacitors. Importantly, these materials maintained efficiency after thousands of charge-discharge cycles, demonstrating their potential as durable, sustainable energy storage solutions.

This research underscores the importance of material optimization, showing how tailored pore structures and morphology can lead to high-capacity, efficient energy storage devices. Such advancements are crucial for powering IoT devices, AI systems, wearable electronics, and self-powered sensors, paving the way for smarter, energy-autonomous technologies.

The workshop fostered valuable international collaboration and knowledge exchange, emphasizing the global effort to push the boundaries of 2D materials. The collective research efforts presented highlight a promising future for energy storage solutions, with ARMS contributing to innovations that could transform multiple technological sectors.

More information about the workshopAdvancing sustainable energy storage with SSbD principles: insights from the Graphene Flagship workshop

On May 15, Suiting Ding (University of Southern Denmark) presented ARMS innovative approach to developing eco-friendly energy storage solutions at a digital workshop, Advancing Sustainability in 2D Materials, organized by the Graphene Flagship. In his presentation, Mr Ding explored a Safe and Sustainable by Design (SSbD) approach, focusing on the integration of 2D materials into next-generation energy storage devices.

ARMS representative highlighted the overarching goal of our project: to create next-generation supercapacitors with an energy density exceeding 50 Wh/kg, while adhering to stringent safety and sustainability standards. He shared details about ARMS’ cutting-edge supercapacitor design, which combines the strengths of DLC and PC materials. Specifically, the device features atomic layer pseudo capacitors (PC) coating on double layer capacitors (DLC) electrode, a design that enhances performance and aligns with our sustainability commitments.

The picture illustrates the innovative architecture for the ARMS supercapacitor.

Mr. Ding also explained how project partners at the University of Southern Denmark apply various SSbD toolboxes to ensure a comprehensive safety and sustainability assessment throughout the project. These include the VEGA toolbox for hazard assessment, ECETOC-TRA for exposure analysis, and Activity-browser/SimaPro for life cycle assessment (LCA). Additionally, ARMS partners incorporate social-LCA and life cycle costing (LCC) to evaluate socio-economic impacts. These tools form an integrated framework that guides our development process, ensuring safety and sustainability are embedded at every stage.

A comprehensive

SSbD framework, containing both safety and sustainability principles.

The digital workshop opened with an introduction to Swedish 2D Sustainability by Elisabeth Sagström-Bäck (SIO Grafen), where she presented a model for promoting responsible development in the field. The next speakers represented two of Graphene Flagship's sibling projects, namely – SAFARI (Dr. Felix Tiniakos from Creative Nano) shared an innovative, fluorine-free process for synthesising Ti₃C₂Tₓ MXene, offering an alternative for its production, and GRAPHERGIA (Matteo Maccanti from Next Technology Tecnotessile), who provided insights into the role of Life Cycle Assessment (LCA) and eco-design in enhancing the sustainability of graphene-based products. Presentations were followed by a panel discussion moderated by Maria Abrahamsson, the Graphene Flagship Director.

The workshop attracted over 100 participants and provided a valuable platform for knowledge exchange. Participants interested in learning more about the SSbD approach were recommended to consult the ARMS D6.1 document available on Zenodo (https://doi.org/10.5281/zenodo.15278965).

For more information about the workshop, please visit the official website: Graphene Flagship - Advancing Sustainability in 2D Materials.

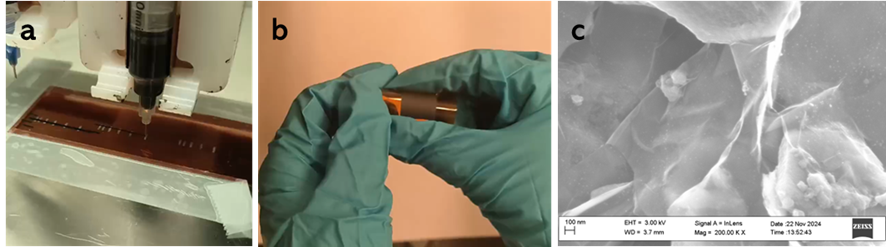

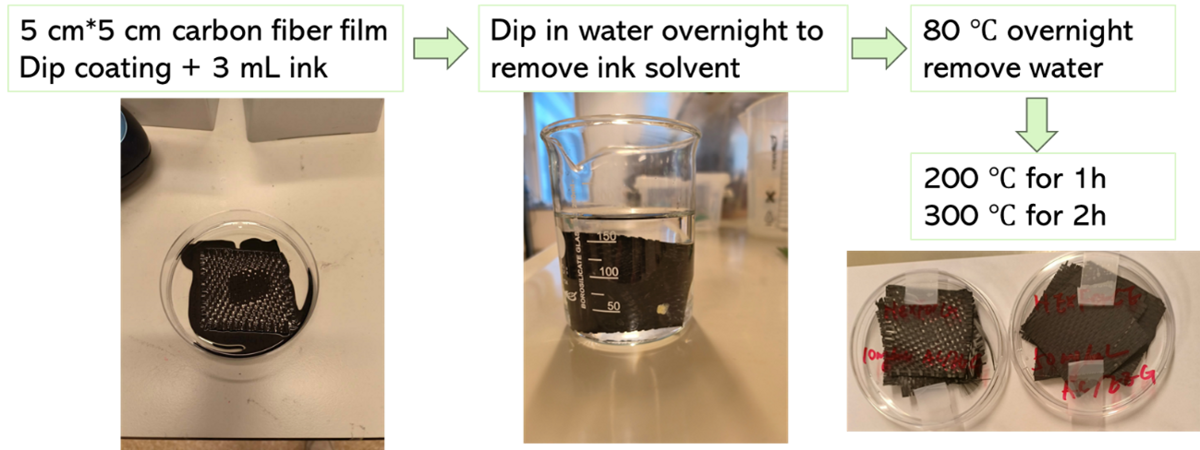

Fabrication of binder-free electrodes via direct ink writing and dip coating modification of carbon fiber sheets

At KTH Royal Institute of Technology, we develop conductive inks for direct ink writing (DIW) and dip coating to fabricate different binder-free electrodes for ARMS supercapacitors. The inks use electrochemically exfoliated graphene (EEG) and activated carbon (AC) as the primary components. After printing and annealing, EEG serves as an effective conductive “binder” to anchor activated carbon (AC) onto flexible substrates such as Kapton, providing strong adhesion and excellent flexibility (Figure b). Using a 3D bioprinter, EEG/AC patterns were successfully printed (Figure a), and their sheet resistance and conductivity were measured using the transmission line method, yielding a conductivity of over 14 S/cm at a thickness of 10 µm. SEM imaging of the printed electrodes revealed thin graphene layers and well-dispersed AC nanoparticles with no presence of the conventional polymeric binders (Figure c).

The photograph of a direct ink writing device (3D bioprinter) to print EEG/AC lines (a). Flexibility test of the printed EEG/AC electrodes on Kapton (b). The SEM images of the printed binder-free EEG/AC electrode (c).

The EEG/AC inks also proved highly effective for a simple 3D dip coating process to modify carbon fiber sheets for structural supercapacitor applications. The dip coating process is illustrated below. Cyclic voltammetry (CV) tests showed that EEG/AC-coated carbon fibers attained more than 30 times higher specific capacitance than the pristine carbon fibers.

In the following project, we will continue optimizing the graphene-enhanced conductive carbon inks to fabricate uniform binder-free electrodes with significantly enhanced electrochemical performance for supercapacitor applications.

ARMS unveils innovative SSbD framework for safe and sustainable electrochemical Energy storage

The ARMS project team from the University of Southern Denmark (Ciprian Cipman and Suiting Ding), with the contribution also from ARMS consortium partners, InnoCell (Jeanne-Louise Schjerning and Steffen Vindt), has released the highly anticipated deliverable, "SSbD Framework for Electrochemical Energy Storage Devices" (D6.1). This report aims to pave the way for innovative solutions in energy storage while prioritizing safety, sustainability, and responsible design.

As the demand for efficient energy storage solutions grows, the development of Advanced Materials (AM) has become crucial. These materials are specifically engineered to enhance physicochemical properties and functional performance, meeting the rigorous requirements of next-generation energy storage technologies. However, the project recognizes the complexities associated with the use of AM, including safety concerns, environmental impacts, resource dependencies, and socio-economic factors.

The newly unveiled SSbD (Safe and Sustainable by Design) framework offers a comprehensive approach to guiding innovation across all stages of electrochemical energy storage development, ranging from early-stage research to market deployment. This hierarchical framework prioritizes safety first, followed by environmental considerations, including circularity, and then social and economic factors.

Integral to the report is a detailed workflow designed to implement SSbD principles in the development of electrochemical energy storage devices. It effectively integrates established safety assessment tools, life cycle modeling frameworks, and best practices drawn from existing literature. By aligning with the European Commission's overarching SSbD methodology, the framework addresses sector-specific sustainability challenges and provides a robust tool for responsible innovation.

The deliverable is pending acceptance by the European Commission.

Read the full report here.

ARMS holds its 4th Consortium Meeting online

On April 24, ARMS held its fourth consortium meeting, bringing together project partners to review progress and plan future steps in advancing supercapacitor technology. The session highlighted achievements across all eight work packages (WPs) and included insights from the External Advisory Board.

WP1, led by the Institute of Solid State Physics, University of Latvia (ISSP UL), reported on the scalable synthesis of graphene-based bio-carbon materials, with promising results from recent experiments on wood-derived carbon. The team is now working on upscaling production for prototype development. KTH Royal Institute of Technology, responsible for WP2, shared progress in fabricating flexible, high-performance graphene-enhanced electrodes, with ongoing efforts to optimize their energy density and flexibility through various manufacturing techniques. WP3, managed by Tampere University (TAU), discussed improvements made via Atomic Layer Deposition (ALD), notably TiO2 coatings that enhance electrode capacitance; future work focuses on process scalability and exploring additional metal oxides.

In WP4, Innocell ApS detailed their development of safe, environmentally friendly electrolytes tailored for flexible and structural supercapacitors, with ongoing optimization and compatibility testing. WP5, led by CIDETEC Energy Storage, outlined plans for integrating these components into prototype supercapacitors; however, device fabrication has not yet commenced. The University of Southern Denmark (SDU), overseeing WP6, emphasized sustainability assessment efforts through a Safe and Sustainable by Design (SSbD) framework, aiming to minimize environmental impact and guide material choices.

Beneq, heading WP7, discussed communication strategies to increase project visibility through social media and the website, while TAU, managing WP8, highlighted the project coordination issues and revealed that the next in-person meeting will take place this October in Odense, Denmark.

The meeting served as a valuable platform for sharing progress, aligning upcoming tasks, and fostering collaboration. As the project advances, the focus remains on refining technologies within each work package and integrating them into a functional supercapacitor to meet growing energy storage demands.

ARMS project spotlight: driving sustainable energy innovations at ICAFM 2025

From March 27 to 29, the 2nd International Conference on Advanced Functional Materials (ICAFM 2025) was held in Kathmandu, Nepal. Project ARMS WP3 leader, Dr. Paul Berger from Tampere University, was a keynote speaker at the event. He presented insights into his collaborative research with colleagues Matti Mäntysalo and Donald Lupo, focusing on the synergy of their efforts and the potential applications of their findings in sustainable energy solutions.

At the conference, Dr. Berger was particularly interested in numerous presentations on supercapacitors utilizing sustainable materials, as this research area is central to the objectives of the ARMS project.

The ICAFM 2025, organized by the Nepal Materials Science Society, brought together leading researchers, academics, and industry professionals in material sciences to discuss cutting-edge advancements and innovations. The event spanned six key areas: advanced materials, energy applications, synthetic and biomedical chemistry, colloids and polymers, separation and analytical chemistry, and the role of chemistry in addressing environmental and interdisciplinary challenges.