Fabrication of binder-free electrodes via direct ink writing and dip coating modification of carbon fiber sheets

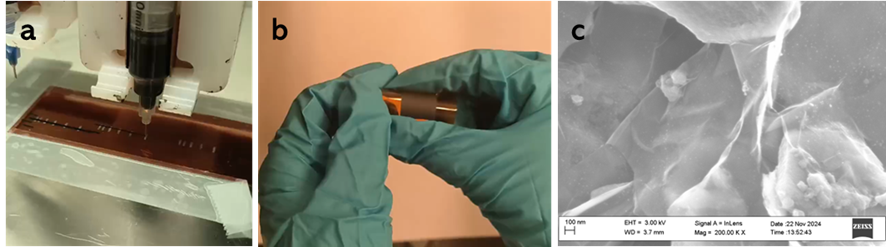

At KTH Royal Institute of Technology, we develop conductive inks for direct ink writing (DIW) and dip coating to fabricate different binder-free electrodes for ARMS supercapacitors. The inks use electrochemically exfoliated graphene (EEG) and activated carbon (AC) as the primary components. After printing and annealing, EEG serves as an effective conductive “binder” to anchor activated carbon (AC) onto flexible substrates such as Kapton, providing strong adhesion and excellent flexibility (Figure b). Using a 3D bioprinter, EEG/AC patterns were successfully printed (Figure a), and their sheet resistance and conductivity were measured using the transmission line method, yielding a conductivity of over 14 S/cm at a thickness of 10 µm. SEM imaging of the printed electrodes revealed thin graphene layers and well-dispersed AC nanoparticles with no presence of the conventional polymeric binders (Figure c).

The photograph of a direct ink writing device (3D bioprinter) to print EEG/AC lines (a). Flexibility test of the printed EEG/AC electrodes on Kapton (b). The SEM images of the printed binder-free EEG/AC electrode (c).

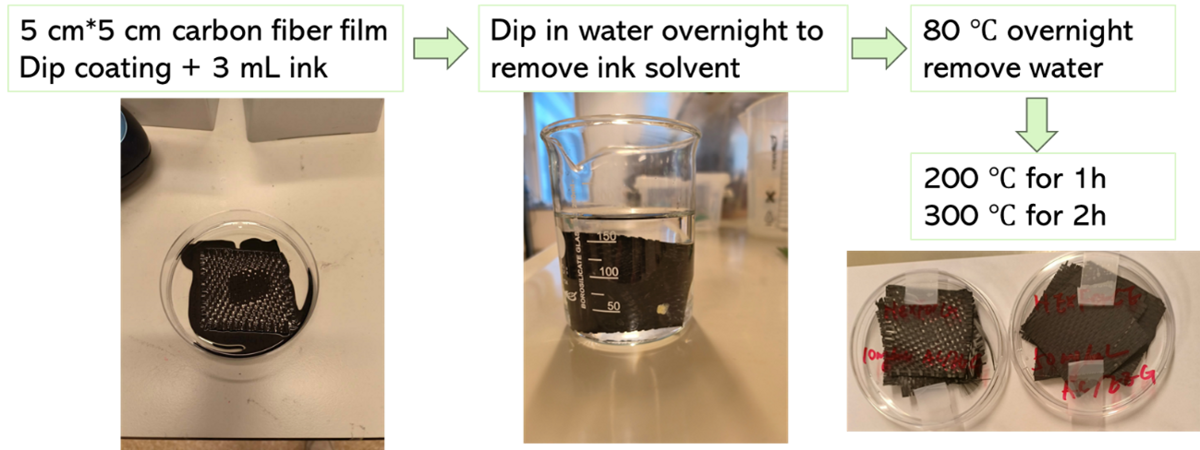

The EEG/AC inks also proved highly effective for a simple 3D dip coating process to modify carbon fiber sheets for structural supercapacitor applications. The dip coating process is illustrated below. Cyclic voltammetry (CV) tests showed that EEG/AC-coated carbon fibers attained more than 30 times higher specific capacitance than the pristine carbon fibers.

In the following project, we will continue optimizing the graphene-enhanced conductive carbon inks to fabricate uniform binder-free electrodes with significantly enhanced electrochemical performance for supercapacitor applications.