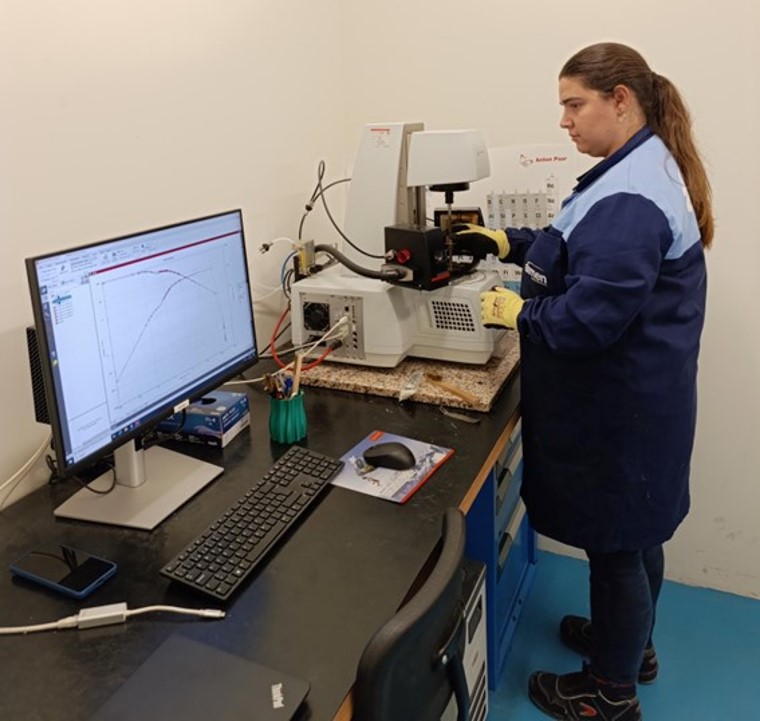

AIMEN advances electrode characterization and electrolyte optimization within the ARMS project

Project ARMS team at the AIMEN Technology Centre

Project ARMS team at the AIMEN Technology Centre

Within the framework of the European project ARMS (Atomic layer-coated gRaphene electrode-based Micro-flexible and Structural supercapacitors), the AIMEN Technology Centre is contributing to the development of structural energy storage materials. AIMEN has recently completed experimental activities within Work Package 2 (Electrode Fabrication) and Work Package 4 (Electrolyte), focused respectively on electrode characterization and electrolyte formulation for structural supercapacitor devices.

As part of WP2, AIMEN has been responsible for activating carbon fibres through pre-treatment processes and supplying the activated materials to project partners for subsequent functionalization. The KTH Royal Institute of Technology applies activated carbon (AC) and electrochemical exfoliated graphene (EEC) coatings by dipping, while the Chalmers University of Technology (CUT) performs graphene and MXene deposition. AIMEN has conducted electrochemical characterization of the coated electrodes to assess their performance under different configurations and operational conditions.

Image 1 and Image 2

Image 1 and Image 2

This work involves the use of Cyclic Voltammetry (CV) and Galvanostatic Charge-Discharge (GCPL) techniques to evaluate the capacitance behaviour of the electrodes in different setups and various electrolyte environments (Image 1 and Image 2), including aqueous (NaCl-H2O), hybrid (NaClO₄-PC/H₂O), and ionic liquid-based systems (EMIMTSFI). The results indicate capacitance increases between 10 and 20 times compared to untreated carbon fibres, highlighting the effect of fibre activation and coating processes. Testing has also identified operational voltage ranges between 1.5 and 2 volts, within which the electrodes maintain stable cycling behaviour.

In WP4, AIMEN is leading the development of electrolyte-resin systems intended for integration into structural supercapacitor manufacturing. This work involves screening epoxy resins and ionic liquid electrolytes to identify formulations that exhibit suitable processability and electrochemical performance.

Image 3

Image 3

AIMEN applies rheological analysis (Image 3) to monitor viscosity changes during thermal curing, assessing the suitability of the material for manufacturing processes such as vacuum-assisted resin infusion (VARI). The ionic conductivity of these systems is evaluated using Electrochemical Impedance Spectroscopy (EIS) before and after curing. Initial results show an increase in ionic conductivity of approximately two orders of magnitude in formulations containing ionic liquids compared to neat resins, while maintaining viscosity ranges suitable for infusion processes.

Next steps in WP2 will include the characterization of activated carbon and graphene-MXene-coated fibres on larger sample formats. In WP4, work will continue on optimizing resin and ionic liquid mixtures. These developments will contribute to WP5 (Supercapacitor Device Integration and Demonstration), where supercapacitor devices will be manufactured using the VARI process. The first manufacturing trials of structural supercapacitors using this approach are planned in the next phase of the project.