ARMS project: Introducing AIMEN’s capabilities, role in the project, and research team

AIMEN Technology Centre, with more than 57 years of history, is currently a national and European benchmark in research, development, and technological innovation in the areas of advanced manufacturing and laser manufacturing, digital technologies for manufacturing, smart materials, smart systems, and recycling; as well as in the provision of differentiating technological services to the industry in the areas of manufacturing with advanced joining technologies, robotics and process digitization, a flexible cross-engineering service highly specialized in welding, corrosion, equipment calculation, product simulation and material tests. AIMEN conducts R&D&I activities and offers technological services for various sectors, including mobility, construction, aerospace, energy, and chemistry, among others. Currently, AIMEN manages 78 EU R&D projects, 20 of which it coordinates.

As part of the ARMS project, AIMEN is concentrating on the desizing and activation of carbon fibre for graphene coating to maximize the capacitance of electrodes. Additionally, the project involves studying the rheology of an electrolyte system compatible with epoxy resin and developing structural supercapacitors through vacuum resin infusion, which will be incorporated into a drone. Furthermore, AIMEN will conduct electrochemical analyses to determine the energy density and power density of the developed structural supercapacitors while also evaluating their mechanical properties.

To date, AIMEN leads task 2.2, in which it collaborates with KTH and Chalmers University, which is responsible for the graphene coating. AIMEN provides the desired carbon fibre and conducts the electrochemical characterization of the coated graphene carbon fibre electrodes (WP2). Additionally, cooperation with Innocell has focused on optimising an electrolyte system for structural supercapacitors (WP4). The rheology tests will provide valuable information for finding a suitable resin/electrolyte system, as well as key parameters of the curing process (curing temperature and time), which will serve as inputs for WP5, focused on the development of structural composite laminates/supercapacitors.

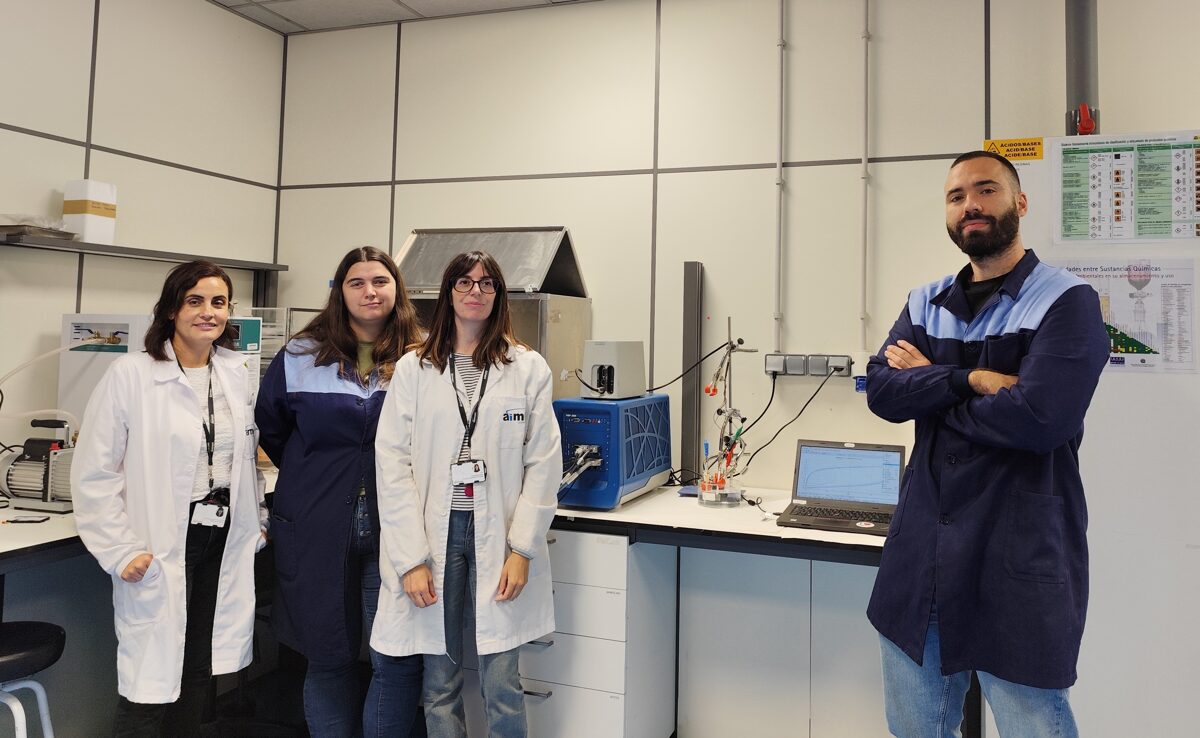

The team at AIMEN involved in the ARMS project consists of four members: Cintia Mateo Mateo, Ignacio Ezpeleta Vázquez-Redonet, Marisol Rivas Caramés, and Lourdes Blanco Salgado.

AIMEN's expertise includes electrochemistry (Potentiostats/Galvanostats, software analysis, and general electrochemical instrumentation), analysis techniques (DSC, TGA, SEM, SEM-EDS), rheology, and mechanical testing (tensile, compression, bending, and fatigue tests), as well as electrical characterization. Additionally, AIMEN has competencies in the development of out-of-autoclave composites, including vacuum infusion setups, degassing systems, ovens, molds, and more.